2 Cores - 5 Cores Galvanised Steel Wire Armoured 0.6/1kv Power Cable

CU/XLPE/PVC/SWA/PVC (2 Cores - 5 Cores)

XLPE Insulated, PVC Bedded, Galvanised Steel Wire Armoured, PVC Sheathed Cable

Application

These power cable for fixed installations such as distribution networks or industrial installations.

Such as Plant engineering; Industrial machinery; Heating and air-conditioning systems; Power stations; Stage applications etc.

Armoured cable suitable for direct burial.

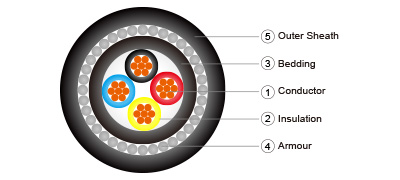

Construction

Conductor: Plain annealed copper, class1 solid or class 2 stranded as per IEC60228.

Flexible class 5 or tinned conductor could be offer upon request.

Insulation: Cross-linked polyethlene (XLPE) compound as per IEC 60502-1.

Insulation Colour:

| Number of Cores | Color Code to IEC 60502-1 | Color Code to BS 5467 |

| 2 | Red & Black | Brown & Blue |

| 3 | Red, Yellow and Blue | Brown, Black and Grey |

| 4 | Red, Yellow, Blue and Black | Blue, Brown, Black and Grey |

| 5 | Red, Yellow, Blue, Black and Green / Yellow |

Green / Yellow, Blue, Brown, Black and Grey |

Assembly: Cores cabled together with PP filler and covered with non-woven tape.

Bedding: Polyvinyl chloride (PVC) compound type ST1 (80°C), ST2 (90°C) of IEC 60502-1.

Bedding Color: Black or other color as per customer request.

Armour: Galvanized steel wire armoured (SWA).

Outer Sheath: Polyvinyl chloride (PVC) compound type ST1 (80°C), ST2 (90°C) of IEC 60502-1.

Outer Sheath Colour: Black or other color as per customer request.

Electrical Characteristics

Recommended rated voltages U0

| Highest system voltage (Um) (kV) |

Rated voltage (U0) (kV) | |

| Categories A and B | Category C | |

| 1,2 | 0,6 | 0,6 |

Routine test voltages

| Rated voltage U0 (kV) | 0,6 |

| Test voltage (kV) | 3,5 |

Maximum conductor temperatures for different types of insulating compound

| Maximum conductor temperature (°C) | |

| Normal operation | Short-circuit (5 s maximum duration) |

| 90 | 250 |

Operating Temperature: -15°C to 90°C

Test Voltage: 3.5 kV for 5 minutes

Installation Reference

Min.Bending Radius (mm): 8 x cable overall diameter

Max.Pulling Tension (N/mm2): 70

Reference Standards

Design Specification: IEC60502-1

Conductor: IEC60228, BS EN60228

Flame Retardancy: IEC60332-1, BS EN60332-1

Dimension

2 Cores

| Nominal Conductor Area (mm2) |

No,and Diameter of Wires (no./mm) |

Thickness of Insulation (mm) |

Thickness of Bedding (mm) |

Diameter of Armour Wire (mm) |

Thickness of Sheath (mm) |

Overall Diameter (mm) |

Approximate Weight (kg/km) |

| 2X1.5 | 7/0.53 | 0.7 | 1 | 0.8 | 1.8 | 13.2 | 325 |

| 2X2.5 | 7/0.67 | 0.7 | 1 | 0.8 | 1.8 | 14 | 372 |

| 2X4 | 7/0.85 | 0.7 | 1 | 0.8 | 1.8 | 15.1 | 438 |

| 2X6 | 7/1.04 | 0.7 | 1 | 1.25 | 1.8 | 17.1 | 645 |

| 2X10 | 7/1.35 | 0.7 | 1 | 1.25 | 1.8 | 19 | 806 |

| 2X16 | 7/1.70 | 0.7 | 1 | 1.25 | 1.8 | 21.1 | 1015 |

| 2X25 | 7/2.14 | 0.9 | 1 | 1.6 | 1.8 | 25.2 | 1517 |

| 2X35 | 7/2.52 | 0.9 | 1 | 1.6 | 1.8 | 27.5 | 1830 |

| 2X50 | 19/1.78 | 1 | 1 | 1.6 | 1.9 | 30.8 | 2259 |

| 2X70 | 19/2.14 | 1.1 | 1.2 | 2 | 2.1 | 36.4 | 3249 |

| 2X95 | 19/2.52 | 1.1 | 1.2 | 2 | 2.2 | 40.4 | 4043 |

| 2X120 | 37/2.03 | 1.2 | 1.2 | 2.5 | 2.4 | 45.4 | 5254 |

| 2X150 | 37/2.25 | 1.4 | 1.4 | 2.5 | 2.5 | 49.9 | 6211 |

| 2X185 | 37/2.52 | 1.6 | 1.4 | 2.5 | 2.7 | 54.9 | 7403 |

| 2X240 | 61/2.25 | 1.7 | 1.6 | 2.5 | 2.9 | 61.3 | 9175 |

| 2X300 | 61/2.52 | 1.8 | 1.6 | 2.5 | 3.1 | 67 | 10939 |

| 2x400 | 61/2.85 | 2 | 1.6 | 3.15 | 3.4 | 75.6 | 14295 |

| 2x500 | 61/3.20 | 2.2 | 1.8 | 3.15 | 3.6 | 83.5 | 17282 |

| 2x630 | 127/2.52 | 2.4 | 1.8 | 3.15 | 3.9 | 92.8 | 21253 |

| 2x800 | 127/2.85 | 2.6 | 2 | 3.15 | 4.3 | 103.4 | 26200 |

| 2x1000 | 127/3.20 | 2.8 | 2 | 3.15 | 4.6 | 113.9 | 31788 |

3 Cores

| Nominal Conductor Area (mm2) |

No,and Diameter of Wires (no./mm) |

Thickness of Insulation (mm) |

Thickness of Bedding (mm) |

Diameter of Armour Wire (mm) |

Thickness of Sheath (mm) |

Overall Diameter (mm) |

Approximate Weight (kg/km) |

| 3X1.5 | 7/0.53 | 0.7 | 1 | 0.8 | 1.8 | 13.6 | 361 |

| 3X2.5 | 7/0.67 | 0.7 | 1 | 0.8 | 1.8 | 14.5 | 420 |

| 3X4 | 7/0.85 | 0.7 | 1 | 1.25 | 1.8 | 16.6 | 629 |

| 3X6 | 7/1.04 | 0.7 | 1 | 1.25 | 1.8 | 17.8 | 742 |

| 3X10 | 7/1.35 | 0.7 | 1 | 1.25 | 1.8 | 19.8 | 954 |

| 3X16 | 7/1.70 | 0.7 | 1 | 1.6 | 1.8 | 22.8 | 1372 |

| 3X25 | 7/2.14 | 0.9 | 1 | 1.6 | 1.8 | 26.5 | 1857 |

| 3X35 | 7/2.52 | 0.9 | 1 | 1.6 | 1.8 | 29 | 2281 |

| 3X50 | 19/1.78 | 1 | 1 | 2 | 2 | 33.5 | 3118 |

| 3X70 | 19/2.14 | 1.1 | 1.2 | 2 | 2.1 | 38.4 | 4107 |

| 3X95 | 19/2.52 | 1.1 | 1.2 | 2 | 2.3 | 42.9 | 5217 |

| 3X120 | 37/2.03 | 1.2 | 1.4 | 2.5 | 2.5 | 48.6 | 6808 |

| 3X150 | 37/2.25 | 1.4 | 1.4 | 2.5 | 2.6 | 53 | 8027 |

| 3X185 | 37/2.52 | 1.6 | 1.4 | 2.5 | 2.8 | 58.3 | 9655 |

| 3X240 | 61/2.25 | 1.7 | 1.6 | 2.5 | 3 | 65.1 | 12085 |

| 3X300 | 61/2.52 | 1.8 | 1.6 | 2.5 | 3.2 | 71.2 | 14540 |

| 3X400 | 61/2.85 | 2 | 1.8 | 3.15 | 3.5 | 80.8 | 19015 |

| 3x500 | 61/3.20 | 2.2 | 1.8 | 3.15 | 3.8 | 89 | 23090 |

| 3x630 | 127/2.52 | 2.4 | 2 | 3.15 | 4.1 | 99.4 | 28777 |

| 3x800 | 127/2.85 | 2.6 | 2 | 3.15 | 4.5 | 110.3 | 35573 |

| 3x1000 | 127/3.20 | 2.8 | 2 | 3.15 | 4.9 | 121.8 | 43549 |

4 Cores

| Nominal Conductor Area (mm2) |

No,and Diameter of Wires (no./mm) |

Thickness of Insulation (mm) |

Thickness of Bedding (mm) |

Diameter of Armour Wire (mm) |

Thickness of Sheath (mm) |

Overall Diameter (mm) |

Approximate Weight (kg/km) |

| 4x1.5 | 7/0.53 | 0.7 | 1 | 0.8 | 1.8 | 14.4 | 406 |

| 4x2.5 | 7/0.67 | 0.7 | 1 | 1.25 | 1.8 | 16.3 | 600 |

| 4x4 | 7/0.85 | 0.7 | 1 | 1.25 | 1.8 | 17.6 | 718 |

| 4x6 | 7/1.04 | 0.7 | 1 | 1.25 | 1.8 | 19 | 859 |

| 4x10 | 7/1.35 | 0.7 | 1 | 1.6 | 1.8 | 22 | 1259 |

| 4x16 | 7/1.70 | 0.7 | 1 | 1.6 | 1.8 | 24.5 | 1628 |

| 4x25 | 7/2.14 | 0.9 | 1 | 1.6 | 1.8 | 28.6 | 2237 |

| 4x35 | 7/2.52 | 0.9 | 1 | 1.6 | 1.9 | 31.6 | 2794 |

| 4x50 | 19/1.78 | 1 | 1.2 | 2 | 2.1 | 36.9 | 3862 |

| 4x70 | 19/2.14 | 1.1 | 1.2 | 2 | 2.3 | 42.1 | 5086 |

| 4x95 | 19/2.52 | 1.1 | 1.4 | 2.5 | 2.5 | 48.5 | 7023 |

| 4x120 | 37/2.03 | 1.2 | 1.4 | 2.5 | 2.6 | 53.1 | 8428 |

| 4x150 | 37/2.25 | 1.4 | 1.4 | 2.5 | 2.8 | 58.2 | 10016 |

| 4x185 | 37/2.52 | 1.6 | 1.6 | 2.5 | 3 | 64.5 | 12185 |

| 4x240 | 61/2.25 | 1.7 | 1.6 | 3.15 | 3.3 | 73.2 | 16156 |

| 4x300 | 61/2.52 | 1.8 | 1.8 | 3.15 | 3.5 | 80.3 | 19518 |

| 4x400 | 61/2.85 | 2 | 1.8 | 3.15 | 3.8 | 89.1 | 24020 |

| 4x500 | 61/3.20 | 2.2 | 2 | 3.15 | 4.1 | 98.6 | 29408 |

| 4x630 | 127/2.52 | 2.4 | 2 | 3.15 | 4.5 | 110 | 36693 |

| 4x800 | 127/2.85 | 2.6 | 2 | 3.15 | 4.9 | 122.1 | 45523 |

| 4x1000 | 127/3.20 | 2.8 | 2 | 3.15 | 5.3 | 134.8 | 55907 |

5 Cores

| Nominal Conductor Area (mm2) |

No,and Diameter of Wires (no./mm) |

Thickness of Insulation (mm) |

Thickness of Bedding (mm) |

Diameter of Armour Wire (mm) |

Thickness of Sheath (mm) |

Overall Diameter (mm) |

Approximate Weight (kg/km) |

| 5x1.5 | 7/0.53 | 0.7 | 1 | 1.25 | 1.8 | 16.2 | 573 |

| 5x2.5 | 7/0.67 | 0.7 | 1 | 1.25 | 1.8 | 17.3 | 671 |

| 5x4 | 7/0.85 | 0.7 | 1 | 1.25 | 1.8 | 18.8 | 812 |

| 5x6 | 7/1.04 | 0.7 | 1 | 1.25 | 1.8 | 20.3 | 981 |

| 5x10 | 7/1.35 | 0.7 | 1 | 1.6 | 1.8 | 23.5 | 1446 |

| 5x16 | 7/1.70 | 0.7 | 1 | 1.6 | 1.8 | 26.4 | 1892 |

| 5x25 | 7/2.14 | 0.9 | 1 | 1.6 | 1.9 | 31.2 | 2644 |

| 5x35 | 7/2.52 | 0.9 | 1.2 | 2 | 2.1 | 35.9 | 3648 |

| 5x50 | 19/1.78 | 1 | 1.2 | 2 | 2.2 | 40.2 | 4580 |

| 5x70 | 19/2.14 | 1.1 | 1.2 | 2.5 | 2.4 | 47 | 6507 |

| 5x95 | 19/2.52 | 1.1 | 1.4 | 2.5 | 2.6 | 53 | 8370 |

| 5x120 | 37/2.03 | 1.2 | 1.4 | 2.5 | 2.8 | 58.2 | 10113 |

| 5x150 | 37/2.25 | 1.4 | 1.6 | 2.5 | 3 | 64.3 | 12131 |

| 5x185 | 37/2.52 | 1.6 | 1.6 | 2.5 | 3.2 | 70.9 | 14693 |

| 5x240 | 61/2.25 | 1.7 | 1.8 | 3.15 | 3.5 | 80.8 | 19549 |

| 5x300 | 61/2.52 | 1.8 | 1.8 | 3.15 | 3.8 | 88.5 | 23599 |

| 5x400 | 61/2.85 | 2 | 2 | 3.15 | 4.1 | 98.6 | 29242 |

| 5x500 | 61/3.20 | 2.2 | 2 | 3.15 | 4.4 | 108.7 | 35726 |

| 5x630 | 127/2.52 | 2.4 | 2 | 3.15 | 4.9 | 121.5 | 44748 |

| 5x800 | 127/2.85 | 2.6 | 2 | 3.15 | 5.3 | 135 | 55631 |

| 5x1000 | 127/3.20 | 2.8 | 2 | 3.15 | 5.8 | 149.3 | 68518 |