Application

These power cable for fixed installations such as distribution networks or industrial installations.

Such as Plant engineering; Industrial machinery; Heating and air-conditioning systems; Power stations; Stage applications etc.

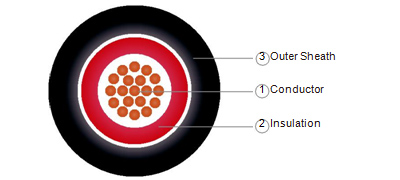

Construction

1 Conductor: Plain annealed copper, class 1 solid or class 2 stranded acc. to IEC 60228.

Flexible class 5 or tinned conductor could be offer upon request.

2 Insulation: Polyviny chloride (PVC) compound as per IEC 60502-1.

Insulation Color Code:

| Number of Cores | Color Code to IEC 60502-1 | Color Code to BS 5467 |

| 1 | Red or Black | Brown or Blue |

3 Outer Sheath: Polyvinyl choride (PVC) compound type ST1 (80°C), ST2 (90°C) of IEC 60502-1.

Outer Sheath Color: Black or other color as per customer request.

Electrical Characteristics

Recommended rated voltages U0

| Highest system voltage | Rated voltage (U0) (kV) | ||||||

| (Um) (kV) | Categories A and B | Category C | |||||

| 1,2 | 0,6 | 0,6 | |||||

| Routine test voltages | |||||||

| Rated voltage U0 (kV) | 0,6 | ||||||

| Test voltage (kV) | 3,5 | ||||||

| Maximum conductor temperatures for different types of insulating compound | |||||||

| PVC Insulation compound | Maximum conductor temperature (°C) | ||||||

| Normal operation | Short-circuit (5 s | ||||||

| maximum duration) | |||||||

| Conductor cross-section ≤300 mm2 | 70 | 160 | |||||

| Conductor cross-section >300 mm2 | 70 | 140 | |||||

Minimum Insulation Resistance at 20°C: 36.7 MΩ·km

Operating Temperature: -15°C to 70°C

Test Voltage: 3.5 kV for 5 minutes

Installation Refference

Min.Bending Radius (mm): 6 x cable overall diameter

Max.Pulling Tension (N/mm2): 50

Reference Standards

Design: IEC60502-1

Conductor: IEC60228, BS EN60228

Flame Retardancy: IEC 60332-1, BS EN60332-1