| Standards: | JISC 3410-1999 IEC 60332-1 IEC 60332-3 Cat.A(for FA-type) |

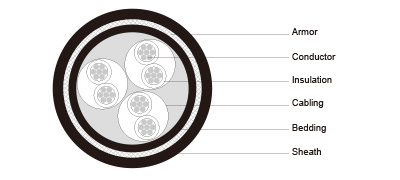

CABLE CONSTRUCTION

| Conductor | TT TTP | Tinned annealed stranded copper (TTY-type) Tinned annealed stranded copper (TTPY-type), class 2 according to IEC 60228 |

| Insulation | 60°C PVC(TTY-type)/ 85°C EPR(TTPY-type) as per JIS C 3401 | |

| Twisting | Two Insulated cores shall be twisted together to form a pair | |

| Cabling | Twisted pairs shall be cabled. Flame retardant & non-hygroscopic fillers may be used | |

| Bedding | Y | PVC as per JIS C 3401 |

| Armor | C | Galvanized steel wire braid |

| Sheath | Y | PVC as per JIS C 3401 |

| Core identification | Printed pair number and Alphabet letter on the white insulation. ex) 4P : (1A, 1B), (2A, 2B), (3A, 3B), (4A, 4B) - 1T, 1Q cable shall be identified by the black number on the white insulation | |

| Outer sheath color | Black |

Cable Parameter

(FA-) TTY,TTPY

| No. of pair, Triad or Quad | Conductor | Thick. of insulation | Thick. of bedding | (FA-) TTY,TTPY | ||||

| Size | Construction | O.D | Nom. overall dia | Tolerance | Cable Weight | |||

| mm² | No./mm | mm | mm | mm | mm | mm | kg/km | |

| 1 | 0.75 | 7/0.37 | 1.1 | 0.7 | 1 | 7.9 | 0.4 | 70 |

| 1T | 0.75 | 7/0.37 | 1.1 | 0.7 | 1.1 | 8.6 | 0.4 | 85 |

| 1Q | 0.75 | 7/0.37 | 1.1 | 0.7 | 1.1 | 9.3 | 0.4 | 105 |

| 2 | 0.75 | 7/0.37 | 1.1 | 0.7 | 1.2 | 12 | 0.6 | 105 |

| 4 | 0.75 | 7/0.37 | 1.1 | 0.7 | 1.3 | 14.2 | 0.6 | 205 |

| 7 | 0.75 | 7/0.37 | 1.1 | 0.7 | 1.4 | 16.9 | 0.7 | 310 |

| 10 | 0.75 | 7/0.37 | 1.1 | 0.7 | 1.5 | 21.7 | 0.9 | 465 |

| 14 | 0.75 | 7/0.37 | 1.1 | 0.7 | 1.6 | 23.5 | 1 | 585 |

| 19 | 0.75 | 7/0.37 | 1.1 | 0.7 | 1.7 | 26.4 | 1.1 | 755 |

| 24 | 0.75 | 7/0.37 | 1.1 | 0.7 | 1.9 | 31.9 | 1.3 | 1030 |

| 30 | 0.75 | 7/0.37 | 1.1 | 0.7 | 2 | 34 | 1.4 | 1220 |

| 37 | 0.75 | 7/0.37 | 1.1 | 0.7 | 2.1 | 36.9 | 1.5 | 1450 |

| 48 | 0.75 | 7/0.37 | 1.1 | 0.7 | 2.3 | 42.8 | 1.7 | 1910 |

(FA-) TTYC,TTPYC

| No. of pair, Triad or Quad | Conductor | Thick. of insulation | Thick. of bedding | Dia. of steel wire | (FA-) TTYC,TTPYC | ||||

| Size | Construction | O.D | Nom. overall dia | Tolerance | Cable Weight | ||||

| mm² | No./mm | mm | mm | mm | mm | mm | mm | kg/km | |

| 1 | 0.75 | 7/0.37 | 1.1 | 0.7 | 1 | 0.3 | 9.2 | 0.4 | 130 |

| 1T | 0.75 | 7/0.37 | 1.1 | 0.7 | 1.1 | 0.3 | 9.9 | 0.4 | 155 |

| 1Q | 0.75 | 7/0.37 | 1.1 | 0.7 | 1.1 | 0.3 | 10.6 | 0.4 | 180 |

| 2 | 0.75 | 7/0.37 | 1.1 | 0.7 | 1.2 | 0.3 | 13.6 | 0.6 | 180 |

| 4 | 0.75 | 7/0.37 | 1.1 | 0.7 | 1.3 | 0.3 | 15.5 | 0.6 | 320 |

| 7 | 0.75 | 7/0.37 | 1.1 | 0.7 | 1.4 | 0.3 | 18.2 | 0.7 | 440 |

| 10 | 0.75 | 7/0.37 | 1.1 | 0.7 | 1.5 | 0.3 | 23 | 0.9 | 640 |

| 14 | 0.75 | 7/0.37 | 1.1 | 0.7 | 1.6 | 0.3 | 24.8 | 1 | 770 |

| 19 | 0.75 | 7/0.37 | 1.1 | 0.7 | 1.7 | 0.3 | 27.7 | 1.1 | 965 |

| 24 | 0.75 | 7/0.37 | 1.1 | 0.7 | 1.9 | 0.4 | 33.7 | 1.3 | 1380 |

| 30 | 0.75 | 7/0.37 | 1.1 | 0.7 | 2 | 0.4 | 35.8 | 1.4 | 1590 |

| 37 | 0.75 | 7/0.37 | 1.1 | 0.7 | 2.1 | 0.4 | 38.7 | 1.5 | 1860 |

| 48 | 0.75 | 7/0.37 | 1.1 | 0.7 | 2.3 | 0.4 | 44.6 | 1.7 | 2380 |

(FA-) TTYCY,TTPYCY

| No. of pair, Triad or Quad | Conductor | Thick. of insulation | Thick. of bedding | Dia. of steel wire | Thick. of covering | (FA-) TTYCY,TTPYCY | ||||

| Size | Construction | O.D | Nom. overall dia | Tolerance | Cable Weight | |||||

| mm² | No./mm | mm | mm | mm | mm | mm | mm | mm | kg/km | |

| 1 | 0.75 | 7/0.37 | 1.1 | 0.7 | 1 | 0.3 | 0.8 | 11 | 0.4 | 170 |

| 1T | 0.75 | 7/0.37 | 1.1 | 0.7 | 1.1 | 0.3 | 0.9 | 11.7 | 0.5 | 205 |

| 1Q | 0.75 | 7/0.37 | 1.1 | 0.7 | 1.1 | 0.3 | 0.9 | 12.6 | 0.5 | 230 |

| 2 | 0.75 | 7/0.37 | 1.1 | 0.7 | 1.2 | 0.3 | 0.9 | 15.5 | 0.7 | 230 |

| 4 | 0.75 | 7/0.37 | 1.1 | 0.7 | 1.3 | 0.3 | 1 | 17.7 | 0.7 | 400 |

| 7 | 0.75 | 7/0.37 | 1.1 | 0.7 | 1.4 | 0.3 | 1.1 | 20.6 | 0.8 | 545 |

| 10 | 0.75 | 7/0.37 | 1.1 | 0.7 | 1.5 | 0.3 | 1.2 | 25.6 | 1 | 775 |

| 14 | 0.75 | 7/0.37 | 1.1 | 0.7 | 1.6 | 0.3 | 1.2 | 27.4 | 1.1 | 920 |

| 19 | 0.75 | 7/0.37 | 1.1 | 0.7 | 1.7 | 0.3 | 1.3 | 30.5 | 1.2 | 1140 |

| 24 | 0.75 | 7/0.37 | 1.1 | 0.7 | 1.9 | 0.4 | 1.4 | 36.7 | 1.5 | 1610 |

| 30 | 0.75 | 7/0.37 | 1.1 | 0.7 | 2 | 0.4 | 1.5 | 39.2 | 1.6 | 1860 |

| 37 | 0.75 | 7/0.37 | 1.1 | 0.7 | 2.1 | 0.4 | 1.6 | 42.3 | 1.6 | 2170 |

| 48 | 0.75 | 7/0.37 | 1.1 | 0.7 | 2.3 | 0.4 | 1.7 | 48.4 | 1.8 | 2760 |