FR200P 07SZ1-R (PH60) (CU/SR/LSZH 450/750V Class 2)

| Application: |

The cables are designed, manufactured and tested for general application in power supply and signal wiring, for emergency circuit and fire circuit control. |

| STANDARDS: |

Basic design to BS 7629-1 |

FIRE PERFORMANCE

|

Circuit Integrity |

IEC 60331-21; BS 6387 CWZ; DIN VDE 0472-814(FE180); BS 8434-1 (30mins); BS 5839-1 Clause 26 2d; CEI 20-36/2-1; SS229-1; NBN C 30-004 (cat. F3); NF C32-070-2.3(CR1) |

|

Circuit Integrity with mechanical shock |

EN 50200(PH60); CEI 20-36/4-0 |

|

Circuit Integrity with mechanical shock & water spray |

EN 50200 annex E |

|

System circuit integrity |

DIN 4102-12, E30 depending on lay system |

|

Flame Retardance (Single Vertical Wire Test) |

EN 60332-1-2; IEC 60332-1-2; BS EN 60332-1-2; VDE 0482-332-1 ; NBN C 30-004 (cat. F1); NF C32-070-2.1(C2); CEI 20-35/1-2; EN 50265-2-1*; DIN VDE 0482-265-2-1* |

|

Reduced Fire Propagation (Vertically-mounted bundled wires & cable test) |

EN 60332-3-24 (cat. C); IEC 60332-3-24; BS EN 60332-3-24; VDE 0482-332-3; NBN C 30-004 (cat. F2); NF C32-070-2.2(C1); CEI 20-22/3-4; EN 50266-2-4*; DIN VDE 0482-266-2-4 |

|

Halogen Free |

IEC 60754-1; EN 50267-2-1; DIN VDE 0482-267-2-1; CEI 20-37/2-1 ; BS 6425-1* |

|

No Corrosive Gas Emission |

IEC 60754-2; EN 50267-2-2; DIN VDE 0482-267-2-2; CEI 20-37/2-2 ; BS 6425-2* |

|

Minimum Smoke Emission |

IEC 61034-1&2; EN 61034 -1&2; DIN VDE 0482-1034-1&2; CEI 20-37/3-1&2; EN 50268-1&2*; BS 7622-1&2* |

|

No Toxic gases |

NES 02-713; NF C 20-454 |

Note: Asterisk * denotes superseded standard.

VOLTAGE RATING

450/750 V

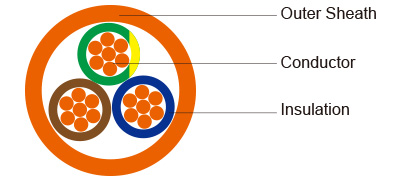

CABLE CONSTRUCTION

- Conductors: Plain annealed copper wire, stranded according to IEC(EN) 60228 class 2.

- Insulation: Fire resistant silicone rubber compound type EI2 as per BS 7655-1.1.

Cabling: The cores are cabled together in concentric layers with suitable non-hygroscopic fillers.

- Outer Sheath: Thermoplastic LSZH compound type LTS3 as per BS 7655-6.1 (Thermosetting LSZH

compound type SW2-SW4 as per BS 7655-2.6 can be offered.)

COLOUR CODE

Insulation Colour:

Without earth conductor

2 cores blue - brown

3 cores brown - black - grey

4 cores blue - brown - black - grey

5 cores blue - brown - black - grey - black

With earth conductor

3 cores yellow/green - blue - brown

4 cores yellow/green - brown - black - grey

5 cores yellow/green - blue - brown - black - grey

Sheath Colour: Colour red (other colours on request)

Physical AND THERMAL PROPERTIES

Temperature range during operation (fixed state): -30°C – +90°C

Temperature range during installation (mobile state): -20°C – +50°C

Minimum bending radius: 7.5 x Overall Diameter

Electrical PROPERTIES

|

Dielectric test: |

2500 V r.m.s. x 5' (core/core) |

|

Insulation resistance |

≥300 MΩ x km (at 20°C) |

|

Short circuit temperature |

350°C |

CONSTRUCTION PARAMETERS

|

Cable Code |

No. of Core X Cross Section |

Nominal Insulation Thickness |

Nominal Sheath Thickness |

Nominal Overall Diameter |

Approx. Weight |

|

|

mm2 |

mm |

mm |

mm |

kg/km |

|

2 core, |

|||||

|

FFX200 07SZ1-R (PH60) |

2x1.5 |

0.8 |

1.0 |

7,8 |

96 |

|

FFX200 07SZ1-R (PH60) |

2x2.5 |

0.9 |

1.1 |

9,2 |

138 |

|

FFX200 07SZ1-R (PH60) |

2x4.0 |

0.9 |

1.2 |

10,5 |

189 |

|

3 core |

|||||

|

FFX200 07SZ1-R (PH60) |

3x1.5 |

0.8 |

1.0 |

8,3 |

116 |

|

FFX200 07SZ1-R (PH60) |

3x2.5 |

0.9 |

1.1 |

9,8 |

169 |

|

FFX200 07SZ1-R (PH60) |

3x4.0 |

0.9 |

1.2 |

11,6 |

246 |

|

4 core |

|||||

|

FFX200 07SZ1-R (PH60) |

4x1.5 |

0.8 |

1.1 |

9,3 |

147 |

|

FFX200 07SZ1-R (PH60) |

4x2.5 |

0.9 |

1.2 |

11,3 |

222 |

|

FFX200 07SZ1-R (PH60) |

4x4.0 |

0.9 |

1.3 |

12,5 |

299 |

|

5 core |

|||||

|

FFX200 07SZ1-R (PH60) |

5x1.5 |

0.8 |

1.1 |

10,5 |

180 |

|

FFX200 07SZ1-R (PH60) |

5x2.5 |

0.9 |

1.2 |

12,3 |

259 |

|

FFX200 07SZ1-R (PH60) |

5x4.0 |

0.9 |

1.3 |

14,0 |

359 |

Electrical PROPERTIES

Conductor Operating Temperature : 90°C

Ambient Temperature : 30°C

Current-Carrying Capacities (Amp)

|

Nominal Cross Section Area |

Reference Method 4 (enclosed in an conduit insulated wall etc) |

Reference Method 3 (enclosed in conduit on a wall or ceiling, or in trunking) |

Reference Method 1 (clipped direct) |

Reference Method 11 (on a perforated cable tray), or Reference Method |

|||

|

one 3-core cable or one 4-core cable 3-phase a.c. |

one 2-core cable single phase a.c. or d.c. |

one 3-core cable or one 4-core cable 3-phase a.c. |

one 2-core cable singlephase a.c. or d.c. |

one 3-core cable or one 4-core cable 3-phase a.c. |

one 2-core cable singlephase a.c. or d.c. |

one 3-core cable or one 4-core cable 3-phase a.c. |

|

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

|

mm2 |

A |

A |

A |

A |

A |

A |

A |

|

1.5 |

16.5 |

22 |

19.5 |

24 |

22 |

26 |

23 |

|

2.5 |

22 |

30 |

26 |

33 |

30 |

36 |

32 |

|

4 |

30 |

40 |

35 |

45 |

40 |

49 |

42 |

Voltage Drop (Per Amp Per Meter)

|

Nominal Cross Section Area |

2-core cable d.c. |

2-core cable single- phase a.c |

3-core or 4-core cable 3-phase a.c. |

|

1 |

2 |

3 |

4 |

|

mm2 |

mV/A/m |

mV/A/m |

mV/A/m |

|

1.5 |

31 |

31 |

27 |

|

2.5 |

19 |

19 |

16 |

|

4 |

12 |

12 |

10 |