JE-H(St)H…Bd FE180 E30 (CU/SR/OS/LSZH 225V Class 1)

JE-H(St)HSWAH…Bd FE180 E30 (CU/SR/OS/LSZH/SWA/LSZH 225V Class 1)

| Application: |

The cables are used for the internal wiring of building when the circuit integrity during fire is paramount. The cables are intended for use in fire fighting plants with special ceramized silicone insulation, with and without aluminum foil and LSZH outer sheath. |

| STANDARDS: |

Basic design to VDE 0815 |

FIRE PERFORMANCE

|

Circuit Integrity |

IEC 60331-23; BS 6387 CWZ; DIN VDE 0472-814(FE180); CEI 20-36/2-1; SS229-1; NBN C 30-004 (cat. F3); NF C32-070-2.3(CR1) |

|

System circuit integrity |

DIN 4102-12, E30 depending on lay system |

|

Flame Retardance (Single Vertical Wire Test) |

EN 60332-1-2; IEC 60332-1-2; BS EN 60332-1-2; VDE 0482-332-1 ; NBN C 30-004 (cat. F1); NF C32-070-2.1(C2); CEI 20-35/1-2; EN 50265-2-1*; DIN VDE 0482-265-2-1* |

|

Reduced Fire Propagation (Vertically-mounted bundled wires & cable test) |

EN 60332-3-24 (cat. C); IEC 60332-3-24; BS EN 60332-3-24; VDE 0482-332-3; NBN C 30-004 (cat. F2); NF C32-070-2.2(C1); CEI 20-22/3-4; EN 50266-2-4*; DIN VDE 0482-266-2-4 |

|

Halogen Free |

IEC 60754-1; EN 50267-2-1; DIN VDE 0482-267-2-1; CEI 20-37/2-1 ; BS 6425-1* |

|

No Corrosive Gas Emission |

IEC 60754-2; EN 50267-2-2; DIN VDE 0482-267-2-2; CEI 20-37/2-2 ; BS 6425-2* |

|

Minimum Smoke Emission |

IEC 61034-1&2; EN 61034 -1&2; DIN VDE 0482-1034-1&2; CEI 20-37/3-1&2; EN 50268-1&2*; BS 7622-1&2* |

|

No Toxic gases |

NES 02-713; NF C 20-454 |

Note: Asterisk * denotes superseded standard.

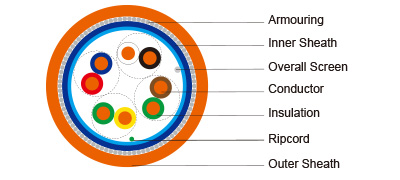

CABLE CONSTRUCTION

Conductors: Solid annealed bare or tinned copper sized 0.6/0.8/0.9mm as per class 1 of VDE 0295/

IEC 60228.

Insulation: Silicone Rubber compound as per DIN VDE 0266.

Cabling Elements: Insulated cores are twisted to form pairs with varying lay length to minimize

crosstalk. Two-pair cable had four cores laid in quad formation.

Cabling: Pairs are cabled together.In cables with 8 pairs or more, 4 pairs are assembled to form a

bunch, and the bunches are then cabled together.

Cable Core Assembly: The twisted pairs are stranded to the core in layers.

Core Wrapping: One or more non hygroscopic polyester tapes are helically or longitudinally laid with

an overlap prior to sheathing.

Screen: A laminated Aluminum/Polyester tape is placed in contact with solid copper 0.6mm or

0.8mm drain wire.

Inner Sheath(optional): PE or thermoplastic LSZH compound type.

Armour (optional): Either corrugated steel tape armour or galvanized steel wire is applied over

an inner polyethylene sheath. For steel tape armour, the 0.15mm thick steel tape is coated with a

copolymer and applied with an overlap. For steel wire armour, single layer of galvanized steel wire

armour is applied.

Ripcord: Nylon ripcord may be placed parallel to the cores to facilitate sheath removal.

Drain Wire: A solid tinned earth/continuity wire shall be laid longitudinally for screened cables.

Outer Sheath: Thermoplastic LSZH compound HM2 as per DIN VDE 0207-24 .

COLOUR CODE

Quad colour in each bundle:

Pair 1: Blue-Red Pair 2: Green-Yellow Pair 3: Green-Brown Pair 4: White-Black

The individual bundles are identified by a numbered helix.

TYPE CODE

JE- Fire alarm cable H Halogen free & zero halogen

Bd Unit stranding. (St) Static shield of Aluminum tape

FE180 Insulation integrity (950°C 180 minutes) E30 30 minutes system circuit integrity

STA Corrugated steel tape SWA Steel wire armour

SWB Steel wire braid

Physical AND THERMAL PROPERTIES

Temperature range during operation (fixed state): -30°C – +90°C

Temperature range during installation (mobile state): -20°C – +50°C

Minimum bending radius: 8 x Overall Diameter (unarmoured cable)

10 x Overall Diameter (armoured cables)

Electrical PROPERTIES

|

Conductor Diameter |

mm |

0.6 |

0.8 |

0.9 |

|

Conductor Size |

mm2 |

0.283 |

0.5 |

0.312 |

|

Maximum Conductor Resistance @20°C |

Ω/km |

63 |

34.6 |

28.0 |

|

Maximum Loop Resistance @20°C |

Ω/km |

130 |

73.2 |

60 |

|

Minimum Insulation Resistance @500V DC @20°C |

MΩ.km |

100 |

100 |

100 |

|

Maximum Average Attenuation @0.8KHz |

dB/km |

1.7 |

1.2 |

0.74 |

|

Nominal Mutual Capacitance @0.8KHz |

nF/km |

120 |

120 |

120 |

|

Maximum Capacitance Unbalance K1 @0.8KHz pair-to-pair |

pF/100m |

200 |

200 |

200 |

|

Working Voltage |

V |

225 |

225 |

225 |

|

Nominal Insulation Thickness |

mm |

0.3 |

0.4 |

0.45 |

|

Nominal Insulated Conductor Diameter |

mm |

1.2 |

1.6 |

1.7 |

CONSTRUCTION PARAMETERS

VDE CODE: JE-SH(St)H…x2x0.8 Bd FE180/E30

|

Cable Code |

No.of Pairs |

Nominal Insulation Thickness |

Nominal Sheath Thickness |

Nominal Overall Diameter |

Approx. Weight |

|

|

|

mm |

mm |

mm |

kg/km |

|

0.8mm Conductor, 1.6mm Insulated Wire |

|||||

|

JE-H(St)H...1x2x0.8 Bd FE180/E30 |

1 |

0.4 |

1.0 |

6.0 |

46 |

|

JE-H(St)H...2x2x0.8 Bd FE180/E30 |

2 |

0.4 |

1.0 |

6.6 |

61 |

|

JE-H(St)H...4x2x0.8 Bd FE180/E30 |

4 |

0.4 |

1.0 |

8.8 |

104 |

|

JE-H(St)H...6x2x0.8 Bd FE180/E30 |

6 |

0.4 |

1.0 |

10.8 |

160 |

|

JE-H(St)H...8x2x0.8 Bd FE180/E30 |

8 |

0.4 |

1.0 |

12.8 |

218 |

|

JE-H(St)H...10x2x0.8 Bd FE180/E30 |

10 |

0.4 |

1.2 |

13.1 |

220 |

|

JE-H(St)H...12x2x0.8 Bd FE180/E30 |

12 |

0.4 |

1.2 |

13.5 |

235 |

|

JE-H(St)H...16x2x0.8 Bd FE180/E30 |

16 |

0.4 |

1.2 |

14.7 |

297 |

|

JE-H(St)H...20x2x0.8 Bd FE180/E30 |

20 |

0.4 |

1.2 |

16.1 |

367 |

|

JE-H(St)H...24x2x0.8 Bd FE180/E30 |

24 |

0.4 |

1.4 |

18.1 |

440 |

|

JE-H(St)H...30x2x0.8 Bd FE180/E30 |

30 |

0.4 |

1.4 |

20.1 |

645 |

|

JE-H(St)H...32x2x0.8 Bd FE180/E30 |

32 |

0.4 |

1.4 |

20.6 |

645 |

|

JE-H(St)H...40x2x0.8 Bd FE180/E30 |

40 |

0.4 |

1.4 |

22.5 |

656 |

|

JE-H(St)H...50x2x0.8 Bd FE180/E30 |

50 |

0.4 |

1.6 |

24.3 |

840 |

VDE CODE: JE-SH(St)HSWAH…x2x0.6/0.8/0.9 Bd FE180/E30

|

Cable Code |

No. of Pairs |

Nominal Insulation Thickness |

Nominal Sheath Thickness |

Nominal Overall Diameter |

Approx. Weight |

|

|

|

mm |

mm |

mm |

kg/km |

|

0.6mm Conductor,1.2mm Insulated Wire |

|||||

|

JE-H(St)HSWAH...2x2x0.6 Bd FE180/E30 |

2 |

0.3 |

1.0/1.8 |

12.1 |

305 |

|

JE-H(St)HSWAH...3x2x0.6 Bd FE180/E30 |

3 |

0.3 |

1.0/1.8 |

12.6 |

325 |

|

JE-H(St)HSWAH...6x2x0.6 Bd FE180/E30 |

6 |

0.3 |

1.0/1.8 |

12.6 |

380 |

|

JE-H(St)HSWAH...8x2x0.6 Bd FE180/E30 |

8 |

0.3 |

1.0/1.8 |

14.6 |

415 |

|

JE-H(St)HSWAH...10x2x0.6 Bd FE180/E30 |

10 |

0.3 |

1.0/1.8 |

16.5 |

450 |

|

JE-H(St)HSWAH...12x2x0.6 Bd FE180/E30 |

12 |

0.3 |

1.0/1.8 |

17.0 |

500 |

|

JE-H(St)HSWAH...20x2x0.6 Bd FE180/E30 |

20 |

0.3 |

1.0/1.8 |

20.5 |

580 |

|

JE-H(St)HSWAH...25x2x0.6 Bd FE180/E30 |

25 |

0.3 |

1.0/1.8 |

21.5 |

940 |

|

JE-H(St)HSWAH...30x2x0.6 Bd FE180/E30 |

30 |

0.3 |

1.0/1.8 |

22.5 |

1300 |

|

0.8mm Conductor, 1.6mm Insulated Wire |

|||||

|

JE-H(St)HSWAH...2x2x0.8 Bd FE180/E30 |

2 |

0.4 |

1.0/1.8 |

14.0 |

415 |

|

JE-H(St)HSWAH...3x2x0.8 Bd FE180/E30 |

3 |

0.4 |

1.0/1.8 |

14.0 |

425 |

|

JE-H(St)HSWAH...6x2x0.8 Bd FE180/E30 |

6 |

0.4 |

1.0/1.8 |

15.0 |

485 |

|

JE-H(St)HSWAH...8x2x0.8 Bd FE180/E30 |

8 |

0.4 |

1.0/1.8 |

17.5 |

520 |

|

JE-H(St)HSWAH...10x2x0.8 Bd FE180/E30 |

10 |

0.4 |

1.2/1.8 |

19.0 |

540 |

|

JE-H(St)HSWAH...12x2x0.8 Bd FE180/E30 |

12 |

0.4 |

1.2/1.8 |

20.5 |

600 |

|

JE-H(St)HSWAH...20x2x0.8 Bd FE180/E30 |

20 |

0.4 |

1.4/1.8 |

24.5 |

1050 |

|

JE-H(St)HSWAH...25x2x0.8 Bd FE180/E30 |

25 |

0.4 |

1.4/1.8 |

27.0 |

1250 |

|

JE-H(St)HSWAH...30x2x0.8 Bd FE180/E30 |

30 |

0.4 |

1.4/1.8 |

28.5 |

1450 |

|

0.9mm Conductor, 1.8mm Insulated Wire |

|||||

|

JE-H(St)HSWAH...10x2x0.9 Bd FE180/E30 |

10 |

0.45 |

1.2/1.8 |

19.7 |

600 |

|

JE-H(St)HSWAH...15x2x0.9 Bd FE180/E30 |

15 |

0.45 |

1.2/1.8 |

23.0 |

1020 |

|

JE-H(St)HSWAH...20x2x0.9 Bd FE180/E30 |

20 |

0.45 |

1.4/1.8 |

25.3 |

1160 |

|

JE-H(St)HSWAH...25x2x0.9 Bd FE180/E30 |

25 |

0.45 |

1.4/1.8 |

27.3 |

1330 |

|

JE-H(St)HSWAH...30x2x0.9 Bd FE180/E30 |

30 |

0.45 |

1.4/1.8 |

29.3 |

1520 |