| Application | The cables are designed to give good protection to the core against inductive interference (RF=0.1).The cables are used for outdoor signaling equipment. |

| Standards | RENFE E.T. 03.365.051.6 |

| Construction | |

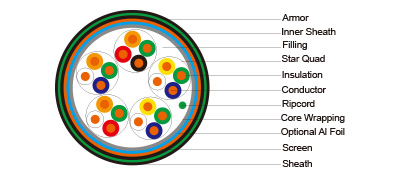

| Conductors: | Solid annealed bare copper 0.9/1.4mm as per ASTM B-3/class 1 of IEC 60228 |

| Insulation: | Solid polyethylene as per ASTM D 1248/IEC 60708 |

| Cabling Element: | Four insulated conductors are twisted together to form a quad |

| Cable Core Assembly: | The cores are cabled together in concentric layers to form the cable core. Units are identified by colour coded binders |

| Core Wrapping: | One or more non-hygroscopic polyester tapes are helically or longitudinally laid with an overlap |

| Electrostatic Screen: | One layer of copper wires 0.12mm is applied helically |

| Bedding: | PE or LSZH |

| Electrostatic Armour: | Two steel tapes of 0.5mm are helically applied with gap. The outer tape will cover the gap left by the inner one |

| Sheath: | PE/PVC or LSZH |

| Ripcord: | Nylon ripcord may be placed parallel to the cores to facilitate sheath removal |

Electrical & Mechanical Properties

|

Nominal Conductor Diameter |

mm |

0.9 |

1.4 |

|

Conductor Size |

mm2 |

0.636 |

1.539 |

|

Maximum Conductor Resistance @20°C |

Ω/km |

28 |

12.1 |

|

Minimum Insulation Resistance @500V DC |

MΩ.km |

35000 |

5000 |

|

Reduction Factor Rk (50Hz) Induced Voltage Em 100V/Km |

|

0.1 |

0.1 |

|

Induced Voltage Em 500V/Km |

|

0.16 |

0.16 |

|

Maximum Resistance Unbalance |

% |

2.5 |

2.5 |

|

Maximum Mutual Capacitance @0.8KHz |

nF/km |

45 |

50 |

|

Maximum Capacitance Unbalance @1KHz pair-to-pair |

pF/500m |

250 |

250 |

|

Maximum Capacitance Unbalance @1KHz pair-to-ground |

pF/500m |

1200 |

1200 |

|

Maximum Average Attenuation @1KHz |

dB/km |

0.7 |

0.46 |

|

Maximum Average Attenuation @10KHz |

dB/km |

1.6 |

0.85 |

|

Maximum Average Attenuation @20KHz |

dB/km |

2.1 |

1.3 |

|

Dielectric Strength Conductor to Conductor 3secs |

V DC |

3000 |

3000 |

|

Conductor to Screen 3secs |

V DC |

3500 |

3500 |

|

Minimum Insulation Thickness |

mm |

0.45 |

0.65 |

|

Maximum Insulated Conductor Diameter |

mm |

1.8 |

2.7 |

Mechanical and Thermal Properties

Temperature range during operation (fixed state): -30°C – +70°C

Temperature range during installation (mobile state): -20°C – +50°C

Minimum bending radius: 15 x Overall Diameter

Colour Code

|

Layer |

Quad Position |

Colour of conductors |

|||

|

1 |

2 |

3 |

4 |

||

|

Centre and even layers |

First |

ORANGE |

GREEN |

RED |

WHITE |

|

Even |

YELLOW |

GREEN |

BLUE |

WHITE |

|

|

Odd |

YELLOW |

GREEN |

RED |

WHITE |

|

|

Last |

ORANGE |

GREEN |

BLUE |

WHITE |

|

|

Odd Layers |

First |

ORANGE |

GREEN |

RED |

BLACK |

|

Even |

YELLOW |

GREEN |

BLUE |

BLACK |

|

|

Odd |

YELLOW |

GREEN |

RED |

BLACK |

|

|

Last |

ORANGE |

GREEN |

BLUE |

BLACK |

|

Dimensions And Weight

|

Cable Code |

Number of Quads |

Nominal Bedding/Sheath Thickness mm |

Nominal Overall Diameter mm |

Nominal Weight kg/km |

|

0.9mm Conductor, 1.8mm Insulated Wire |

||||

|

UE-TP365-2Y(CTS)2Y(DSTA)Y1Q09-RF01 |

1 |

1.5/1.6 |

24.5 |

1300 |

|

UE-TP365-2Y(CTS)2Y(DSTA)Y3Q09-RF01 |

3 |

1.5/1.6 |

25.5 |

1425 |

|

UE-TP365-2Y(CTS)2Y(DSTA)Y5Q09-RF01 |

5 |

1.5/1.6 |

28.0 |

1650 |

|

UE-TP365-2Y(CTS)2Y(DSTA)Y7Q09-RF01 |

7 |

1.5/1.6 |

29.5 |

1800 |

|

UE-TP365-2Y(CTS)2Y(DSTA)Y25Q09-RF01 |

25 |

1.7/1.8 |

41.0 |

3175 |

|

UE-1.4mm Conductor, 2.7mm Insulated Wire |

||||

|

UE-TP365-2Y(CTS)2Y(DSTA)Y3Q14-RF01 |

3 |

1.5/1.6 |

28.5 |

1775 |

|

UE-TP365-2Y(CTS)2Y(DSTA)Y5Q14-RF01 |

5 |

1.6/1.8 |

33.0 |

2200 |

|

UE-TP365-2Y(CTS)2Y(DSTA)Y7Q14-RF01 |

7 |

1.6/1.8 |

35.5 |

2525 |

|

UE-TP365-2Y(CTS)2Y(DSTA)Y10Q14-RF01 |

10 |

1.6/1.8 |

39.0 |

2975 |