| Applications | These cables are designed for use in submersible pumpsand similar applications in water for industrial use up toa water depth of 10 m and water temperature-rangesup to 40℃, also approved for dry, humid and wetapplications. |

| Standards | DIN VDE 0282 Part1 and Part 16 HD 22.1 HD 22.16 S1 |

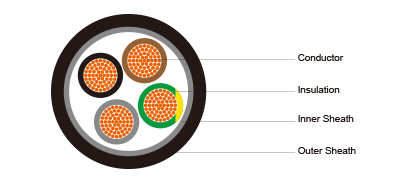

| Construction | |

| Conductors | Strandedcopper conductor, class 5 according to DIN VDE 0295/IEC 60228. |

| Insulation | Rubbertype EI4according to DIN VDE 0282 Part 16. |

| InnerSheath(for ≥ 10 mm² ormore than 5 cores) | Rubbertype EM2/EM3according to DIN VDE 0282 Part 16. |

| Outer Sheath | Rubber type EM2according to DIN VDE 0282 Part 16. |

Dimensions and Weight:

|

Number of Cores×Nominal Cross Section |

Insulation Thickness |

Thickness of Inner Sheath |

Thickness of Outer Sheath |

Minimum Overall Diameter |

Maximum Overall Diameter |

Nominal Weight |

|

No.×mm² |

mm |

mm |

mm |

mm |

mm |

kg/km |

|

1×1.5 |

0.8 |

- |

1.4 |

5.7 |

6.7 |

60 |

|

2×1.5 |

0.8 |

- |

1.5 |

8.5 |

10.5 |

120 |

|

3G1.5 |

0.8 |

- |

1.6 |

9.2 |

11.2 |

170 |

|

4G1.5 |

0.8 |

- |

1.7 |

10.2 |

12.5 |

210 |

|

5G1.5 |

0.8 |

- |

1.8 |

11.2 |

13.5 |

260 |

|

7G1.5 |

0.8 |

1.0 |

1.6 |

14.0 |

17.0 |

360 |

|

12G1.5 |

0.8 |

1.2 |

1.7 |

17.6 |

20.5 |

515 |

|

19G1.5 |

0.8 |

1.4 |

2.1 |

20.7 |

26.3 |

795 |

|

24G1.5 |

0.8 |

1.4 |

2.1 |

24.3 |

28.5 |

920 |

|

1×2.5 |

0.9 |

- |

1.4 |

6.3 |

7.5 |

75 |

|

2×2.5 |

0.9 |

- |

1.7 |

10.2 |

12.5 |

170 |

|

3G2.5 |

0.9 |

- |

1.8 |

10.9 |

13.0 |

230 |

|

4G2.5 |

0.9 |

- |

1.9 |

12.1 |

14.5 |

290 |

|

5G2.5 |

0.9 |

- |

2.0 |

13.3 |

16.0 |

360 |

|

7G2.5 |

0.9 |

1.1 |

1.7 |

17.0 |

20.0 |

510 |

|

12G2.5 |

0.9 |

1.2 |

1.9 |

20.6 |

23.5 |

740 |

|

19G2.5 |

0.9 |

1.5 |

2.2 |

24.4 |

30.9 |

1190 |

|

24G2.5 |

0.9 |

1.6 |

2.3 |

28.8 |

33.0 |

1525 |

|

1×4 |

1.0 |

- |

1.5 |

7.2 |

8.5 |

100 |

|

2×4 |

1.0 |

- |

1.8 |

11.8 |

14.5 |

195 |

|

3G4 |

1.0 |

- |

1.9 |

12.7 |

15.0 |

305 |

|

4G4 |

1.0 |

- |

2.0 |

14.0 |

17.0 |

400 |

|

5G4 |

1.0 |

- |

2.2 |

15.6 |

19.0 |

505 |

|

1×6 |

1.0 |

- |

1.6 |

7.9 |

9.5 |

130 |

|

2×6 |

1.0 |

- |

2.0 |

13.1 |

16.0 |

285 |

|

3G6 |

1.0 |

- |

2.1 |

14.1 |

17.0 |

380 |

|

4G6 |

1.0 |

- |

2.3 |

15.7 |

19.0 |

550 |

|

5G6 |

1.0 |

- |

2.5 |

17.5 |

21.0 |

660 |

|

1×10 |

1.2 |

- |

1.8 |

9.5 |

11.5 |

195 |

|

2×10 |

1.2 |

1.2 |

1.9 |

17.7 |

21.5 |

565 |

|

3G10 |

1.2 |

1.3 |

2.0 |

19.1 |

22.5 |

715 |

|

4G10 |

1.2 |

1.4 |

2.0 |

20.9 |

24.5 |

875 |

|

5G10 |

1.2 |

1.4 |

2.2 |

22.9 |

27.0 |

1095 |

|

1×16 |

1.2 |

- |

1.9 |

10.8 |

13.0 |

280 |

|

2×16 |

1.2 |

1.3 |

2.0 |

20.2 |

23.5 |

795 |

|

3G16 |

1.2 |

1.4 |

2.1 |

21.8 |

25.5 |

1040 |

|

4G16 |

1.2 |

1.4 |

2.2 |

23.8 |

28.0 |

1280 |

|

5G16 |

1.2 |

1.5 |

2.4 |

26.4 |

31.0 |

1610 |

|

1×25 |

1.4 |

- |

2.0 |

12.7 |

15.0 |

405 |

|

4G25 |

1.4 |

1.6 |

2.2 |

28.9 |

33.0 |

1890 |

|

5G25 |

1.4 |

1.7 |

2.7 |

32.0 |

36.0 |

2335 |

|

1×35 |

1.4 |

- |

2.2 |

14.3 |

17.0 |

545 |

|

4G35 |

1.4 |

1.7 |

2.7 |

32.5 |

36.5 |

2505 |

|

5G35 |

1.4 |

1.8 |

2.8 |

35.0 |

39.5 |

2718 |

|

1×50 |

1.6 |

- |

2.4 |

16.5 |

19.5 |

730 |

|

4G50 |

1.6 |

1.9 |

2.9 |

37.7 |

42.0 |

3350 |

|

5G50 |

1.6 |

2.1 |

3.1 |

41.0 |

46.0 |

3804 |

|

1×70 |

1.6 |

- |

2.6 |

18.6 |

22.0 |

955 |

|

4G70 |

1.6 |

2.0 |

3.2 |

42.7 |

47.0 |

4785 |

|

1×95 |

1.8 |

- |

2.8 |

20.8 |

24.0 |

1135 |

|

4G95 |

1.8 |

2.3 |

3.6 |

48.4 |

54.0 |

6090 |

|

1×120 |

1.8 |

- |

3.0 |

22.8 |

26.5 |

1560 |

|

4G120 |

1.8 |

2.4 |

3.6 |

53.0 |

59.0 |

7550 |

|

5G120 |

1.8 |

2.8 |

4.0 |

59.0 |

65.0 |

8290 |

|

1×150 |

2.0 |

- |

3.2 |

25.2 |

29.0 |

1925 |

|

4G150 |

2.0 |

2.6 |

3.9 |

58.0 |

64.0 |

8495 |

|

1×185 |

2.2 |

- |

3.4 |

27.6 |

31.5 |

2230 |

|

4G185 |

2.2 |

2.8 |

4.2 |

64.0 |

71.0 |

9850 |

|

1×240 |

2.4 |

- |

3.5 |

30.6 |

35.0 |

2945 |

|

1×300 |

2.6 |

- |

3.6 |

33.5 |

38.0 |

3495 |

|

1×630 |

3.0 |

- |

4.1 |

45.5 |

51.0 |

7020 |