| Applications | These cables are used for the connection of mobile machines under extremelyhigh mechanical loads, predominantly in miningsituations, e.g. for coal-cutting machines, also can beoperated via guide pulleys (cable cars) or used as areeling cable (LHD), suitable for extreme bending loads, high tensile stress,and impact and crushing loads. |

| Standards | VDE 0250 Part 812 |

| Construction | |

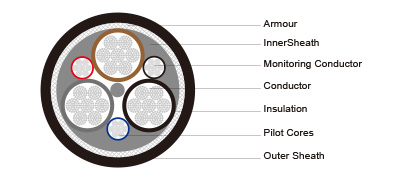

| Conductors | Flexible stranded tinned copper conductor. |

| Insulation | Heatresistant3GI3 rubber based on EPR. |

| Outer Conductor Layer | Easy strippable outer conductive layer. |

| Pilot Cores | Copper and steel conductor capable ofexpansion and compression with 3GI3 EPRrubber insulation. |

| Monitoring Conductor | Copper and steel conductorcapable of expansion and compression covert with semiconductive rubber compound. |

| InnerSheath | Rubber type GM1b. |

| Armour/Earth Conductor | Concentric earth conductor as tensile-stress-resistant braided armour of combined copper-steel wires. |

| Outer Sheath | Rubber type 5GM5, abrasion and tear resistant, oil resistant and flame retardant. |

Dimensions and Weight

|

Number of Cores×Nominal Cross Section |

Minimium Overall Diameter |

Maximum Overall Diameter |

Nominal Weight |

|

No.×mm² |

mm |

mm |

kg/km |

|

3×16/16KON+2ST+UEL |

38.5 |

41.5 |

2430 |

|

3×25/16KON+2ST+UEL |

41.0 |

44.5 |

3050 |

|

3×35/16KON+2ST+UEL |

44.5 |

48.0 |

3620 |

|

3×50/25KON+2ST+UEL |

50.0 |

54.0 |

4810 |

|

3×70/35KON+2ST+UEL |

54.5 |

58.5 |

5890 |

|

3×95/50KON+2ST+UEL |

62.5 |

66.5 |

7800 |

|

3×35/16KON+3ST+3UEL |

44.5 |

48.0 |

3860 |

|

3×50/25KON+3ST+3UEL |

50.0 |

54.0 |

5050 |

|

3×70/35KON+3ST+3UEL |

54.5 |

58.5 |

6000 |

|

3×95/50KON+3ST+3UEL |

62.5 |

66.5 |

8050 |

|

3×120/70KON+3ST+3UEL |

67.5 |

72.0 |

9380 |

|

3×150/70KON+3ST+3UEL |

74.5 |

79.0 |

11120 |